Overview Index

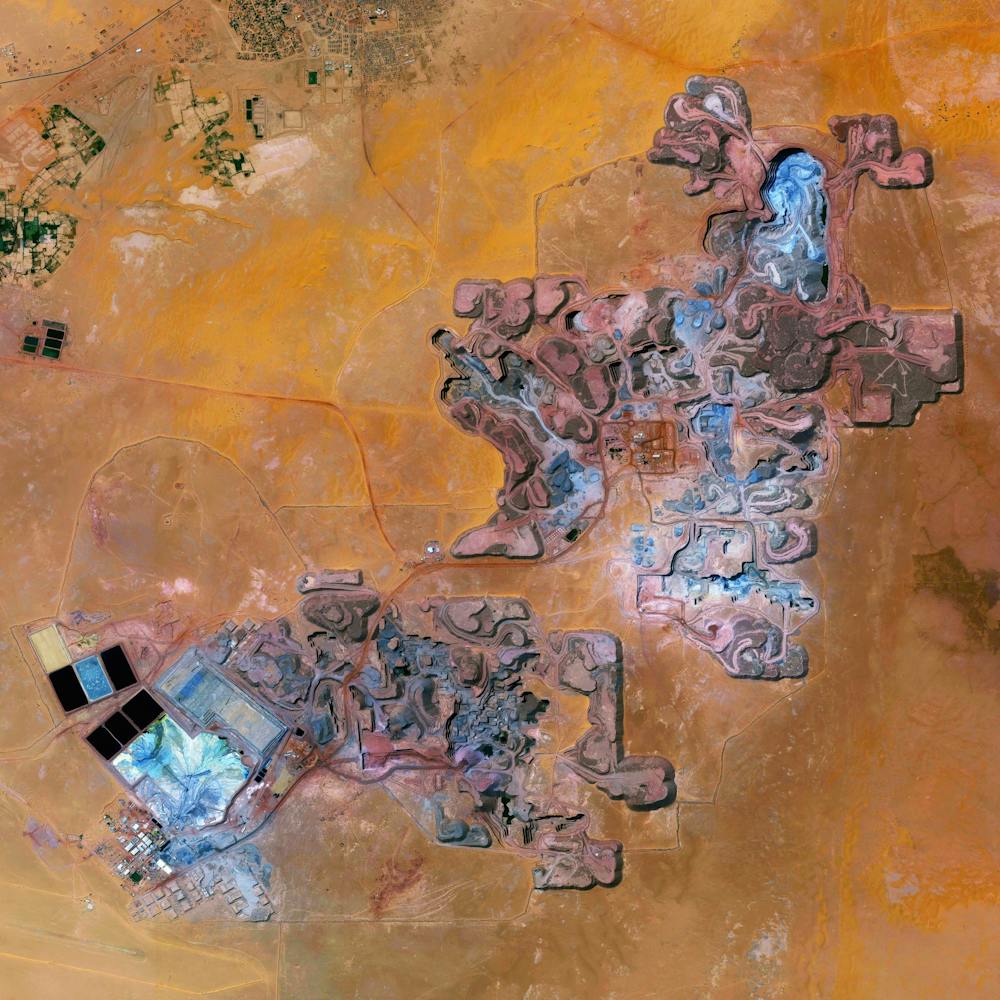

Arlit Uranium Mine

18.760752°, 7.318642° - Arlit, NigerThe Arlit Uranium mine is located in Arlit, Niger. French nuclear power generation as well as the French nuclear weapons program are dependent on the uranium that is extracted from the mine - more than 3400 tonnes per year.

Maxar Technologies

Bandar Imam Khomeini Chemical Complex

30.471667°, 49.099444° - Khuzestan Province, IranThe Bandar Imam Khomeini petrochemical complex is Iran’s largest supplier of petrochemicals for export, generating millions of tons of petroleum-based products every year. Located in Iran’s southwestern Khuzestan Province, the complex is seen in this Overview adjacent to Musa Bay, a shallow estuary that empties into the Persian Gulf.

Maxar Technologies

Battle Mountain Pit Mine

40.338167°, -117.202417° - Lander County, Nevada, USAVivid blue water fills an open-pit mine near the town of Battle Mountain in Lander County, Nevada. Founded in 1861, Lander County made its way onto the map as copper and gold mining boomed there throughout the late 19th century. Today, fewer than 6,000 people live in the 5,500-square-mile county.

Maxar Technologies

Bingham Canyon Mine

40.523000°, -112.151000° - Salt Lake City, UtahThe Bingham Canyon Mine is an open-pit mine in Salt Lake City, Utah. At 2.5 miles wide and 0.6 miles deep, it is the largest man made excavation in the world. On April 10th, 2013, a landslide took place at the pit that was the single largest non-volcanic landslide to ever happen in North America. The amount of debris that fell into the mine was roughly equivalent to 1/6 of the volume of all humans alive on Earth.

Maxar Technologies

Bingham Creek Reservoir

40.561472°, -112.088611° - Salt Lake County, UtahCopper residue stains the walls of the Bingham Creek Reservoir in Salt Lake County, Utah. The reservoir is owned by the Kennecott Utah Copper Corporation and is used to store wastewater from the nearby Bingham Canyon Mine, one of the largest open-pit copper mines in the world.

Nearmap

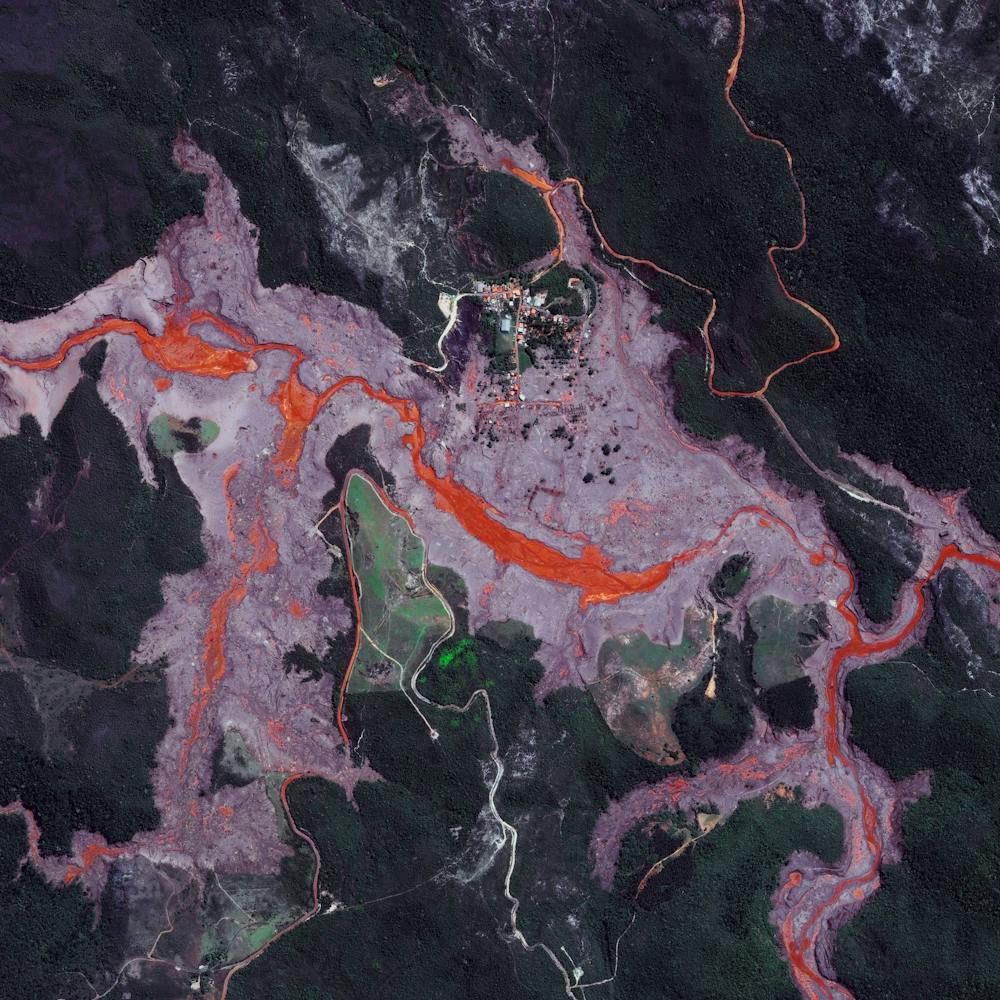

Brazilian Mine Disaster Juxtapose

-20.237096°, -43.421697° - Bento Rodriguez, BrazilOn 5 November 2015, two dams collapsed at an iron ore mine in southeastern Brazil. News outlets estimated that approximately 62 million cubic metres (81 million cubic yards) of toxic waste water (similar to the red mud on previous page) was unleashed. As seen in this Juxtapose, the immediate release of sludge wiped out the village of Bento Rodrigues, resulting in the death of 17 people. Because of this pollution, more than half a million people did not have access to clean drinking water or water to irrigate crops for an extended period of time. Furthermore, within two weeks of the dam rupture, the contaminated waters had spread across a 644-kilometre (400-mile) stretch of the Doce River and entered into the Atlantic Ocean, killing significant amounts of plant and animal life along the way. Officials are concerned that the toxins will continue to threaten the Comboios Nature Reserve, a protected area for the endangered leatherback turtle.

Maxar Technologies

Brazilian Mining Waste Disaster

-20.119722°, -44.121389° - Brumadinho, BrazilLast Friday, a tailings dam collapsed at an iron ore mine in Brumadinho, Brazil, spilling out more than 3 billion gallons (12 billion liters) of red mud and debris. Click the image below to see the areas around the dam before and after its collapse.Homes, cars, buses and other structures were engulfed by the sludgy spill, and the region’s entire ecosystem is expected to be impacted by the contaminants in the tailings — which include waste rock and other residue left over after ore extraction. As of today, media sources are reporting at least 99 people have died and more than 270 are missing.

Maxar Technologies

Carrara Marble

44.100989°, 10.131797° - Carrara, ItalyMarble quarriers are visible in Carrara, Italy. The blue-grey marble that is extracted here is widely used in sculpture like Michelangelo’s David and in building decor like that of The Pantheon. With more than 650 active or abandoned quarry sites, more marble has been extracted here than any other place on earth. /// Created by @dailyoverview, source imagery: @maxartechnologies

Maxar Technologies

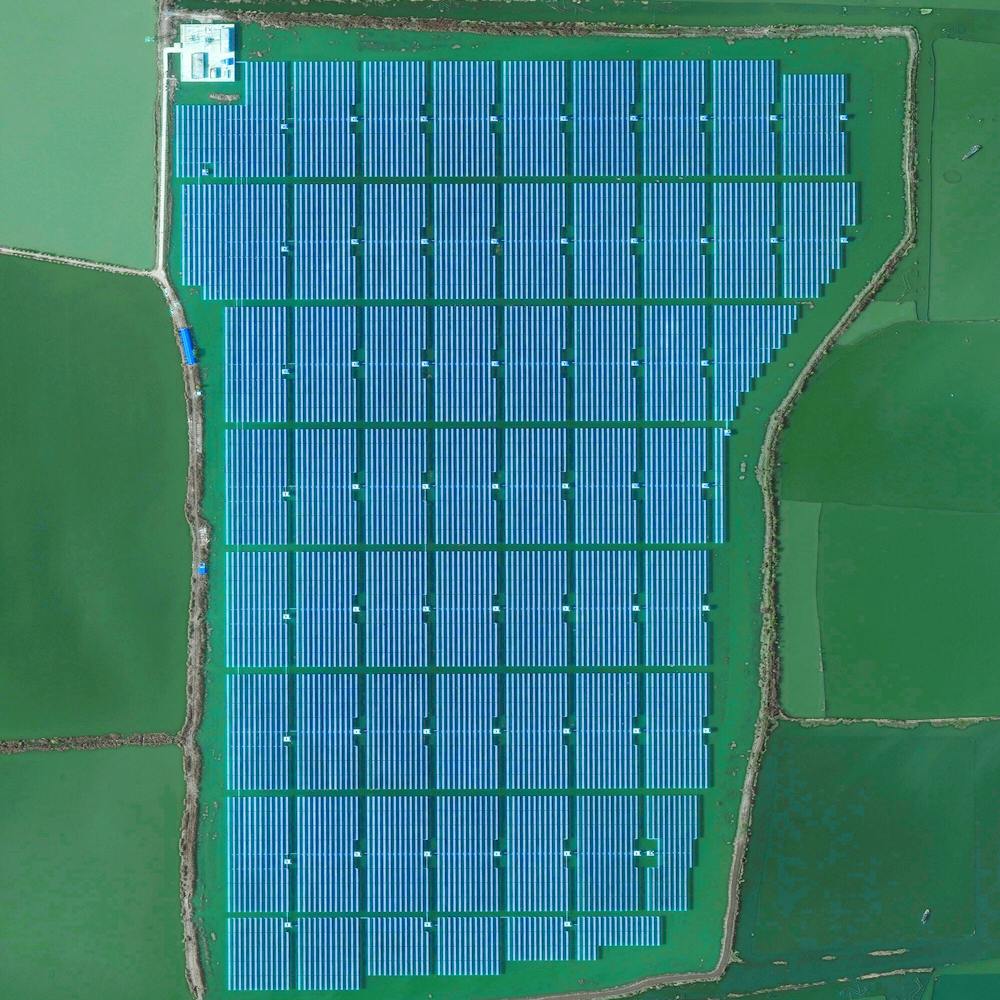

Chinese Floating Solar Farm

32.580123°, 116.589000° - Huainan, ChinaSolar panels sitting atop a man-made lake in Huainan, China, make up the world’s largest floating solar farm. Sungrow Huainan Solar Farm is capable of producing enough electricity to power 15,000 homes and floats above an area formerly used for coal mining.

Maxar Technologies

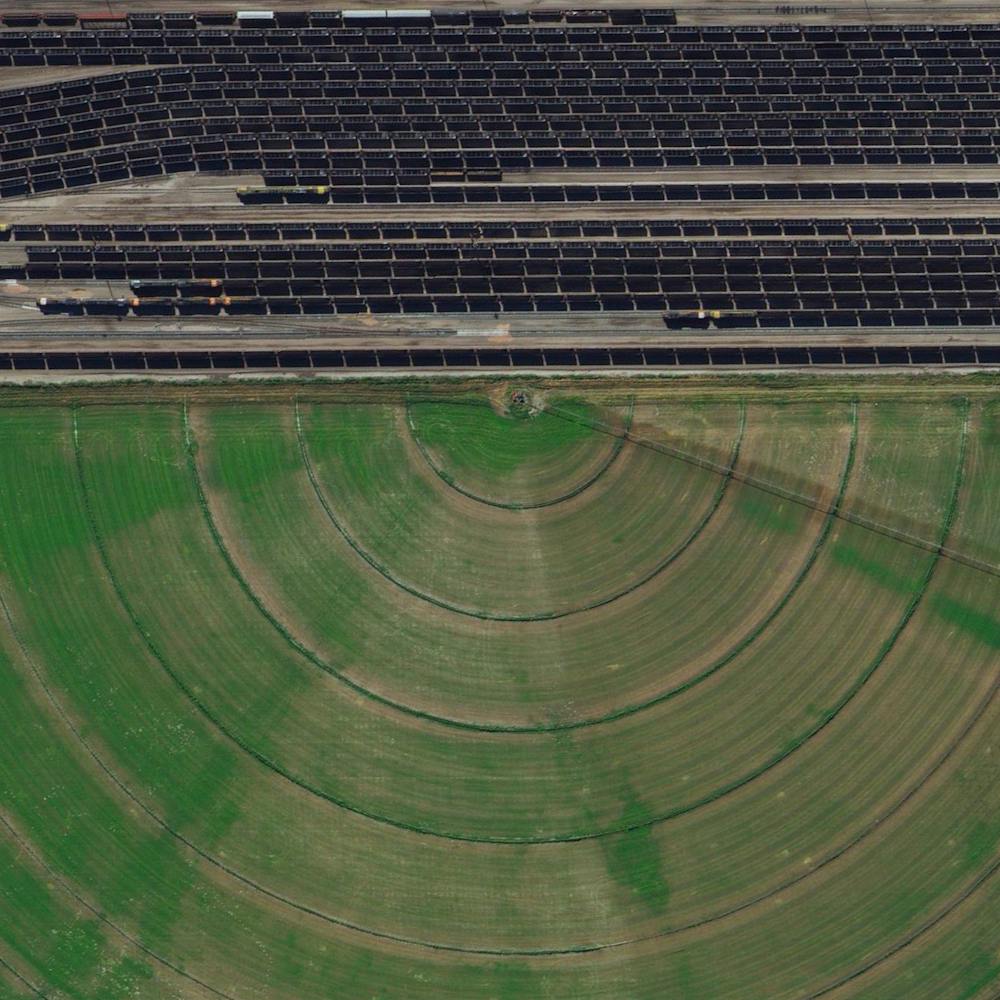

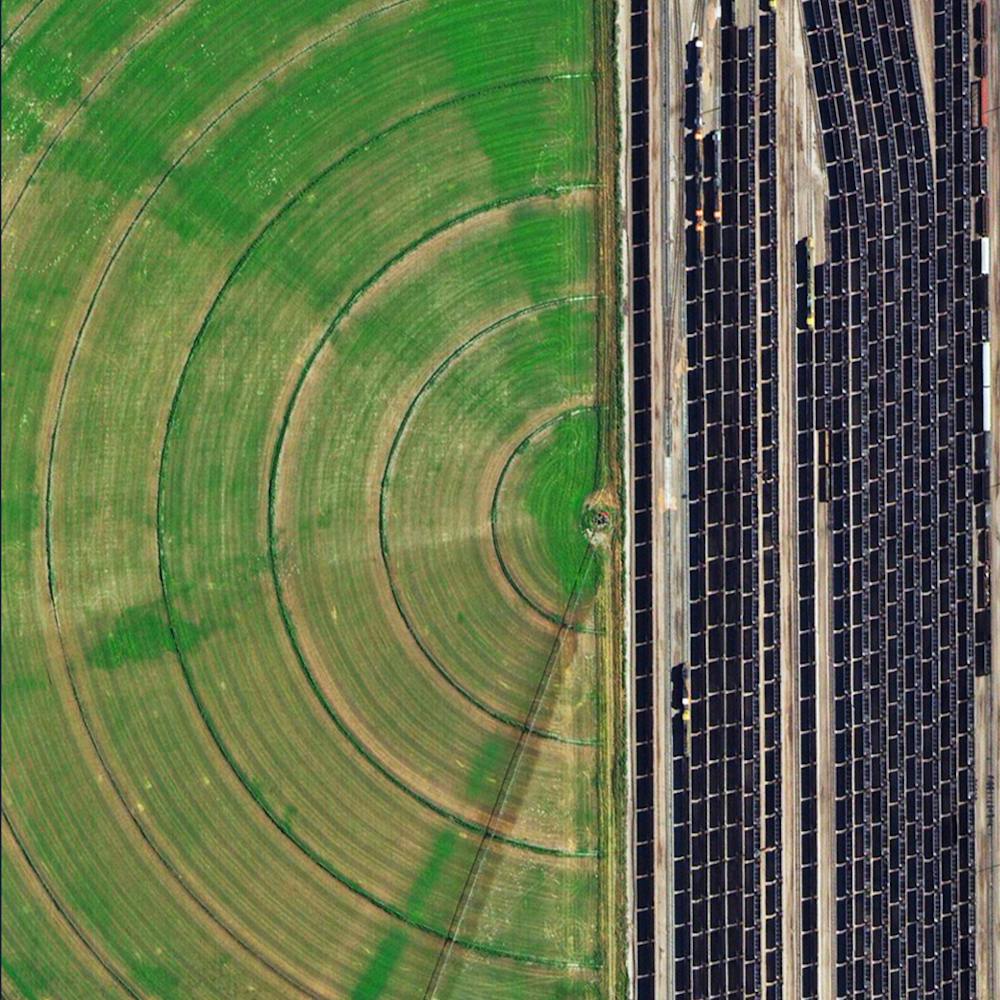

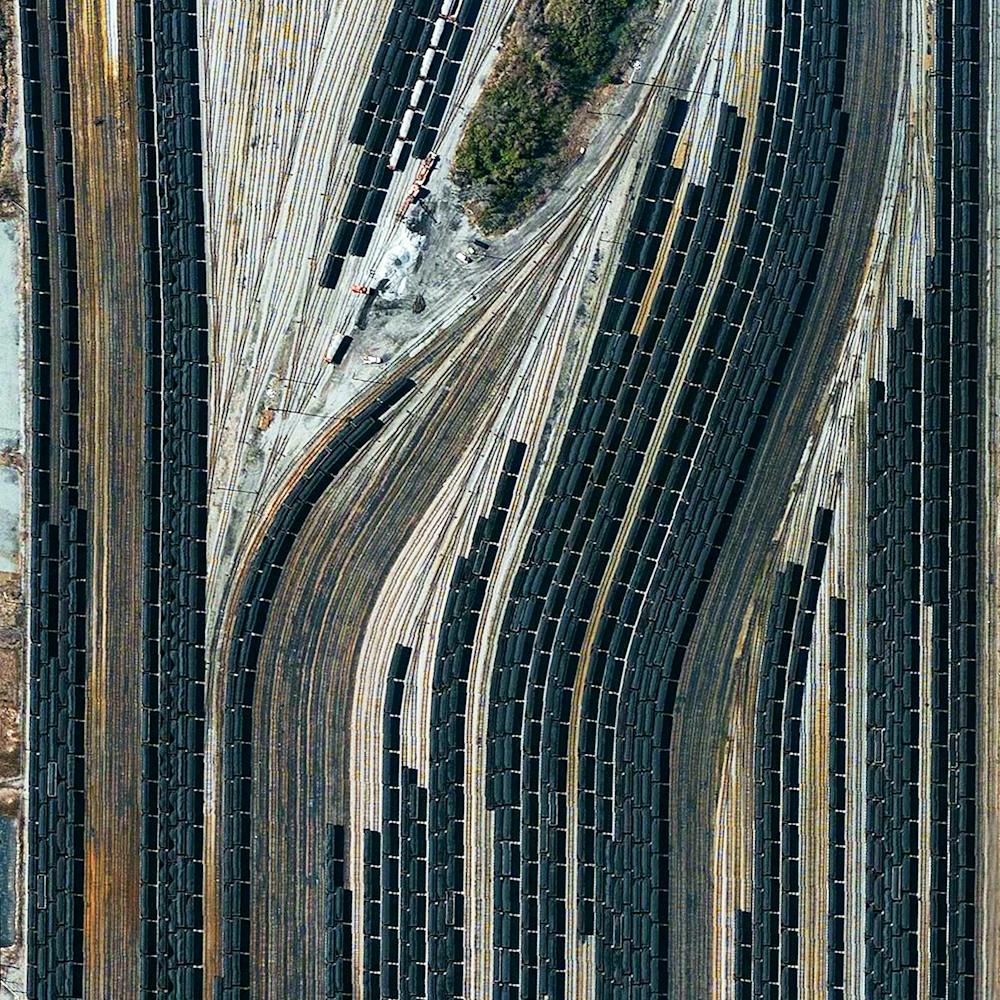

Coal trains

42.082523°, -102.890046° - Alliance, Nebraska, USACoal trains - some full, others empty - idle in a railyard next to a pivot irrigation circle in Alliance, Nebraska, USA. The city is located in the Powder River Basin - one of the world’s largest coal-mining areas - and serves as a stopping point for trains en route to power plants in the Midwest and Southern parts of the country.

Maxar Technologies

Coal Trains in Alliance, Nebraska

42.082523°, -102.890045° - 42.082523°, -102.890045°Coal trains — some full, others empty — idle in a railyard next to a pivot irrigation circle in Alliance, Nebraska, USA. The city is located in the Powder River Basin — one of the world’s largest coal-mining areas — and serves as a stopping point for trains en route to power plants in the Midwest and Southern parts of the country.

Maxar Technologies

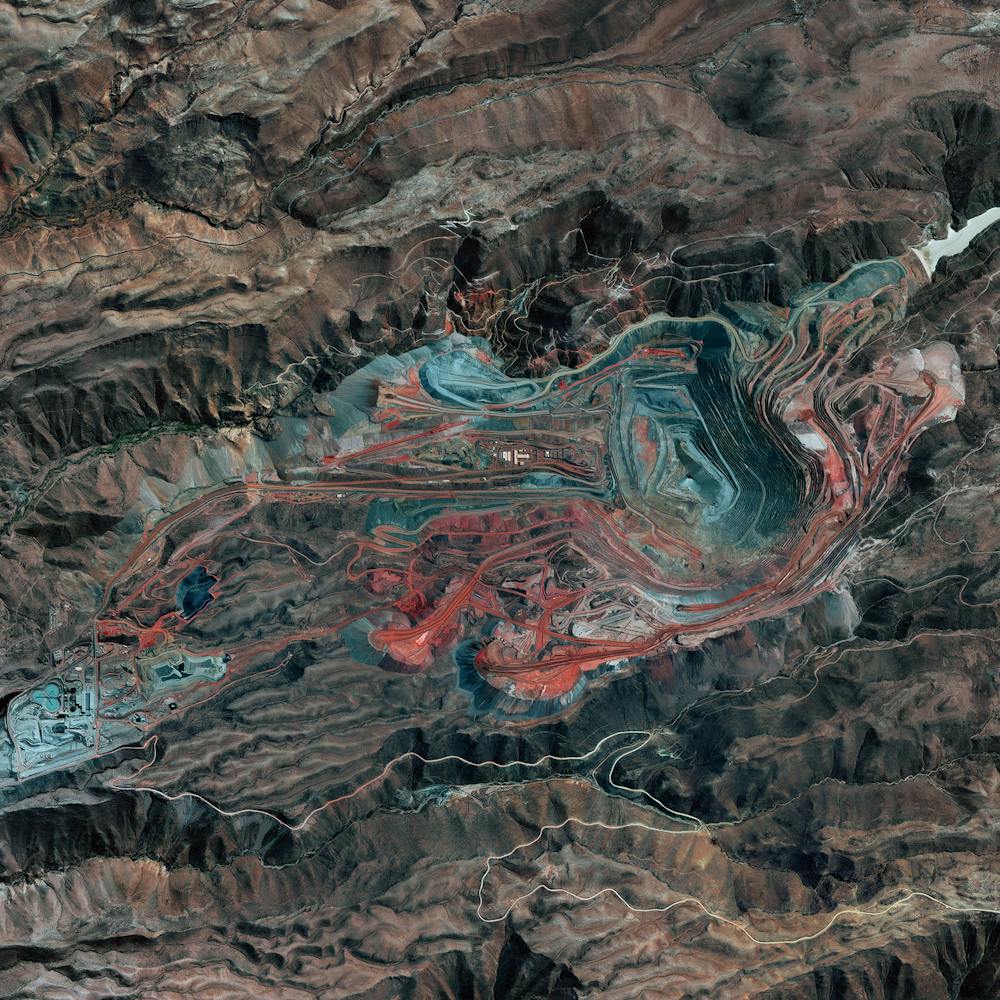

Cuajone Mine

-17.060772°, -70.729159° - Peruvian Andes, PeruThe Cuajone Mine is located near the district of Torata, in the southern range of the Peruvian Andes. The mine is best known for its copper deposits, but it other materials such as silver, zinc, and molybdenum have been extracted there as well. Operations began in 1970, and by 2009 accounted for 16% of the country's copper production.

Maxar Technologies

Diavik Diamond Mine

64.496111°, -110.273333° - Lac de Gras, CanadaThe Diavik Diamond Mine is located on the Lac de Gras lake in the Northwest Territories of Canada, 120 miles (193km) south of the Arctic Circle. The mine produces approximately 7.5 million carats of diamonds each year. In standard weight, that’s an annual output of 1500 kilograms or 3,300 pounds. In this Overview, the most distinguishable areas of the facility are its two primary open pits, waste ponds, processing facilities, and an airstrip capable of landing aircraft as large as 737s and C-130s.

Maxar Technologies

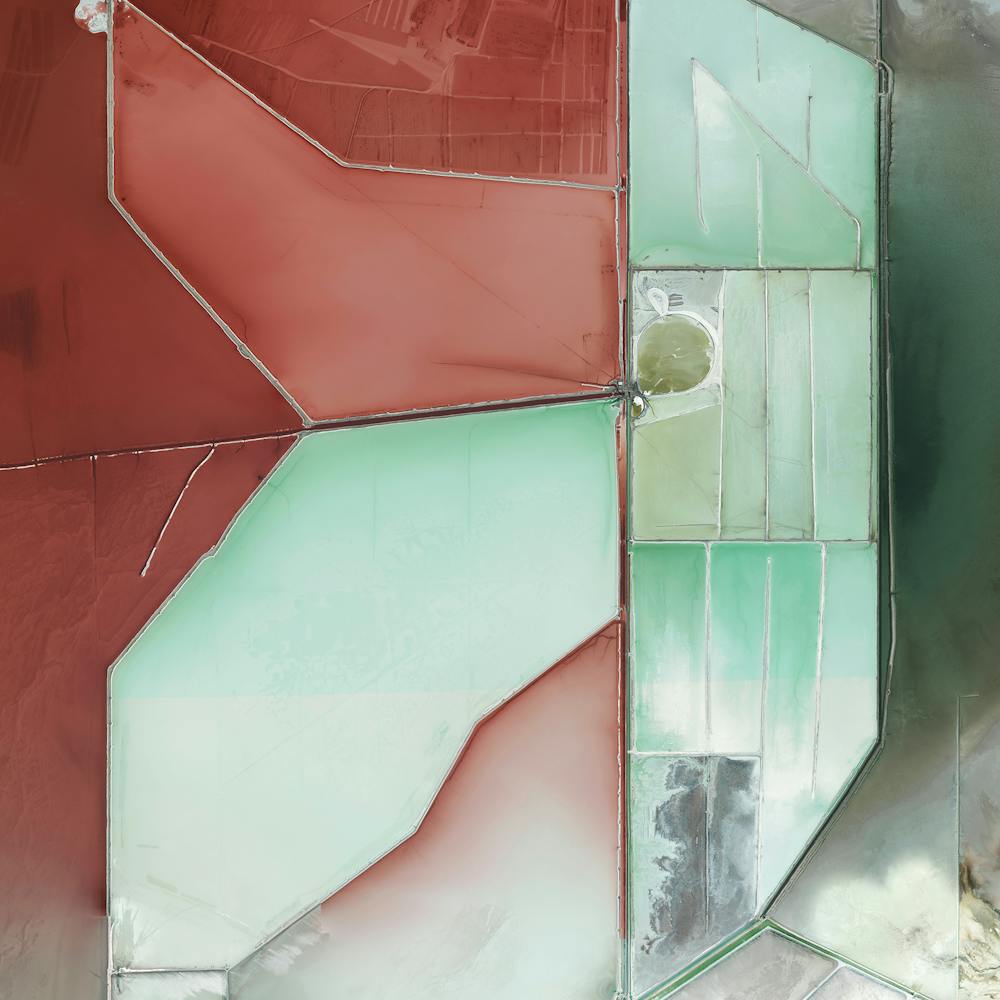

Evaporation ponds

40.792726°, -112.592892° - Great Salt Lake, UtahEvaporation ponds in the Great Salt Lake, Utah are pictured in this Overview. The Great Salt Lake contributes an estimated $1.3 billion annually to Utah’s economy, including $1.1 billion from industry, which is mostly due to mineral extraction. Minerals extracted from the lake include sodium chloride, potassium sulfate, and magnesium-chloride.

Maxar Technologies

Great Salt Lake Evaporation Ponds

41.294750°, -112.258444° - Great Salt Lake, Utah, USAEvaporation ponds in the Great Salt Lake, Utah, are pictured in this Overview. The Great Salt Lake contributes an estimated $1.3 billion annually to Utah’s economy, including $1.1 billion from industry, which is mostly due to mineral extraction. Minerals extracted from the lake include sodium chloride, potassium sulfate, and magnesium-chloride.

Maxar Technologies

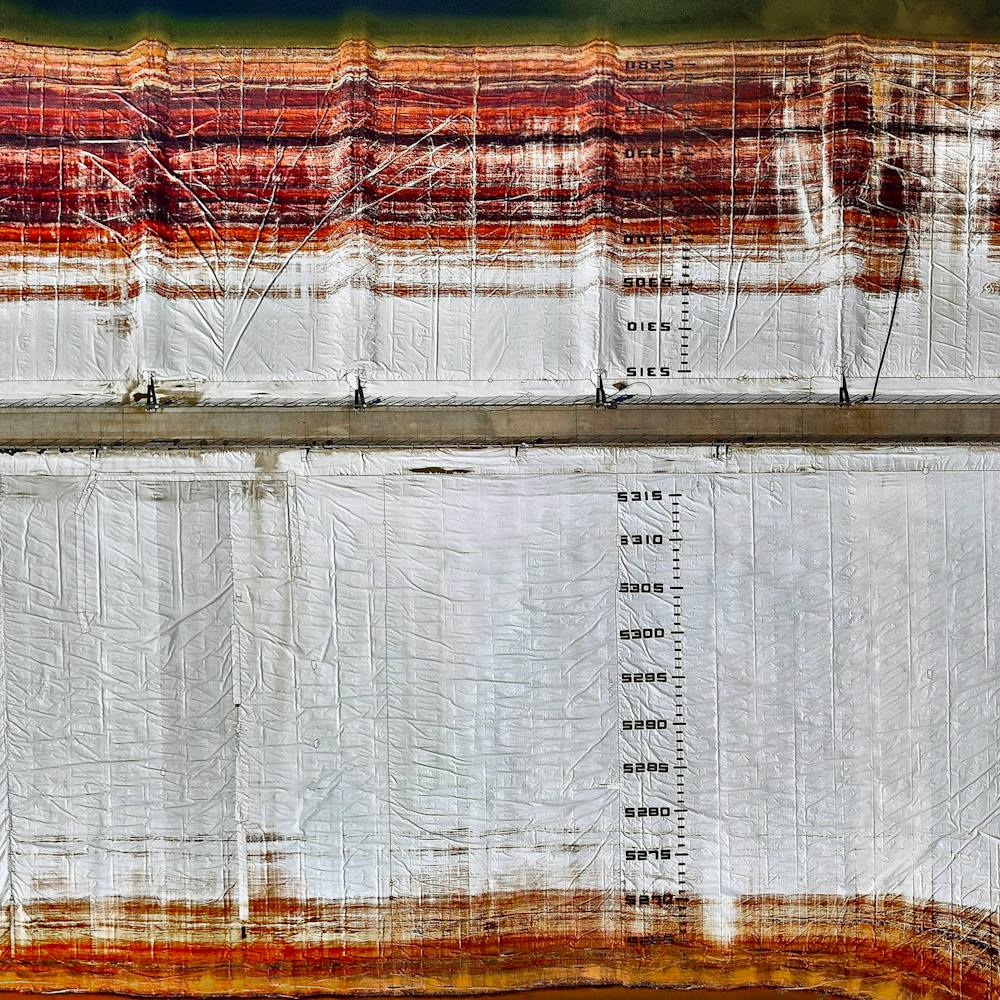

Great Sandy Desert

-20.000000°, 125.000000° - -20.000000°, 125.000000°The Great Sandy Desert is the second-largest desert in Australia, covering 110,036 square miles (284,993 square km) in the northwestern part of the continent. Despite its name, the western portion of the desert is almost devoid of sand, but is characterized by complex geology — as shown in this Overview. The Great Sandy Desert is sparsely populated by indigenous Australian communities and mining centers.

United States Geological Survey

Ile de Noirmoutier Salt Pans

46.999512°, -2.282612° - Ile de Noirmoutier, FranceSalt pans are visible on Ile de Noirmoutier, an island off the coast of France. Here, more than 800 tonnes of salt are extracted annually through evaporation. Sea water is channeled into the basins via canals, which pass through reservoirs that get progressively shallower. Over time, evaporation causes the salt to crystallize and it is then carefully extracted from the pans.

Maxar Technologies

Iron Ore Mine Tailings Pond

46.407676°, -87.530954° - Negaunee, Michigan, USATailings are the waste and by-products generated by mining operations. The tailings seen here were pumped into the Gribbens Basin, next to the Empire and Tilden Iron Ore Mines in Negaunee, Michigan, USA. Once the materials are pumped into the pond, they are mixed with water to create a sloppy form of mud known as slurry. The slurry is then pumped through magnetic separation chambers to extract usable ore and increase the mine’s total output. For a sense of scale, this Overview shows approximately 2.5 square kilometers (1 square mile) of the basin.

Maxar Technologies

Jwaneng Diamond Mine

-24.523050°, 24.699750° - BostwanaThe Jwaneng Diamond Mine in Botswana is the richest diamond mine in the world, with an annual output of approximately 15.6 million carats. Mine richness takes into account the rate of diamond extraction combined with the quality of the diamonds that are mined (sale price per weight). To extract the diamonds, the facility produces 9.3 million tonnes of ore and an additional 37 million tonnes of waste rock per year.

Maxar Technologies

Kawah Ijen

-8.058000°, 114.242000° - Java, IndonesiaKawah Ijen is a stratovolcano in the East Java Province of Indonesia. It has a 0.6-mile-wide (1 km) turquoise-colored acidic crater lake, which is the site of a major sulfur mining operation. At night, when sulfuric gases make contact with fresh air, electric blue flames can be seen rising from volcano up to 16 feet (5 m) high.

Maxar Technologies

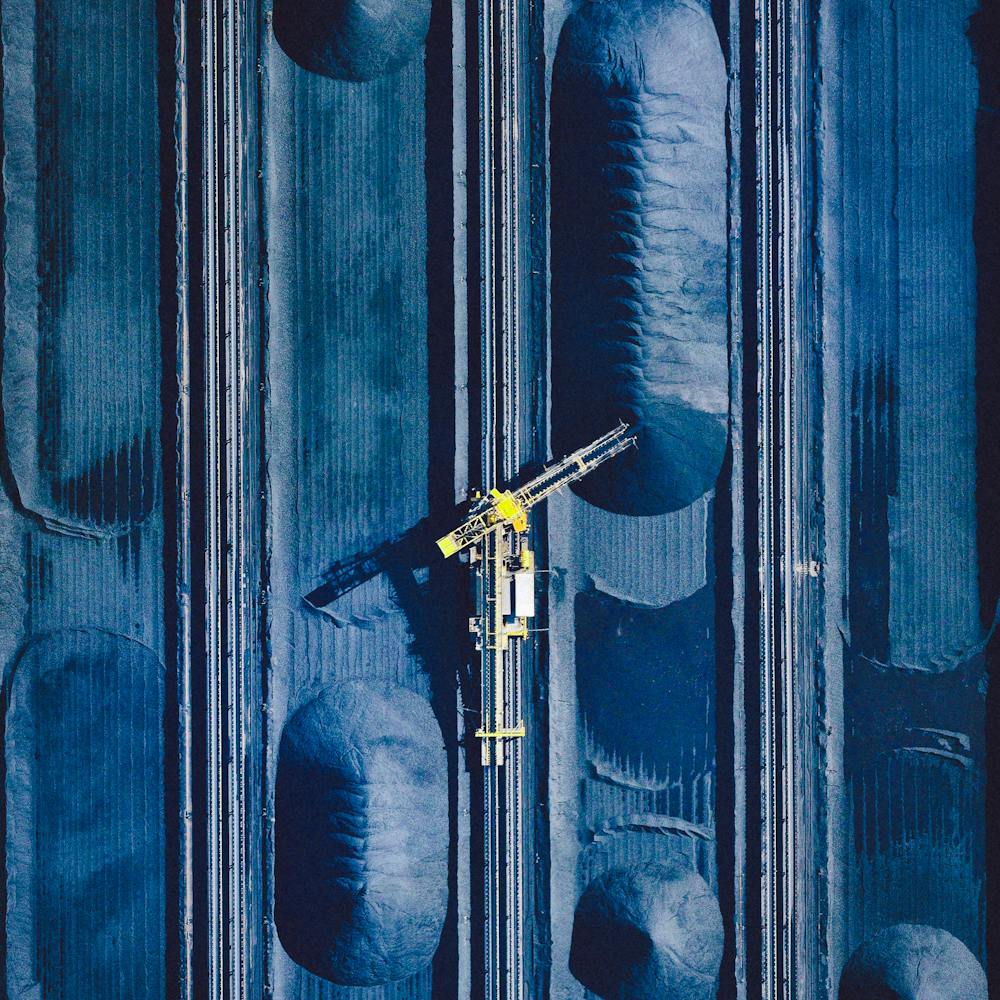

Kooragang Island Coal

-32.875306°, 151.767778° - Kooragang Island, New South Wales, AustraliaLarge piles of coal await shipment on Kooragang Island, part of the Port of Newcastle in New South Wales, Australia. Established in 1984 with a capacity of 15 million tonnes per annum, the island now has a capacity of at least 120 million tonnes per annum. In July 2013, a record 10.3 million tonnes of coal was processed through the Port of Newcastle, with 83 of 114 ships loaded at the Kooragang Island terminal.

Nearmap

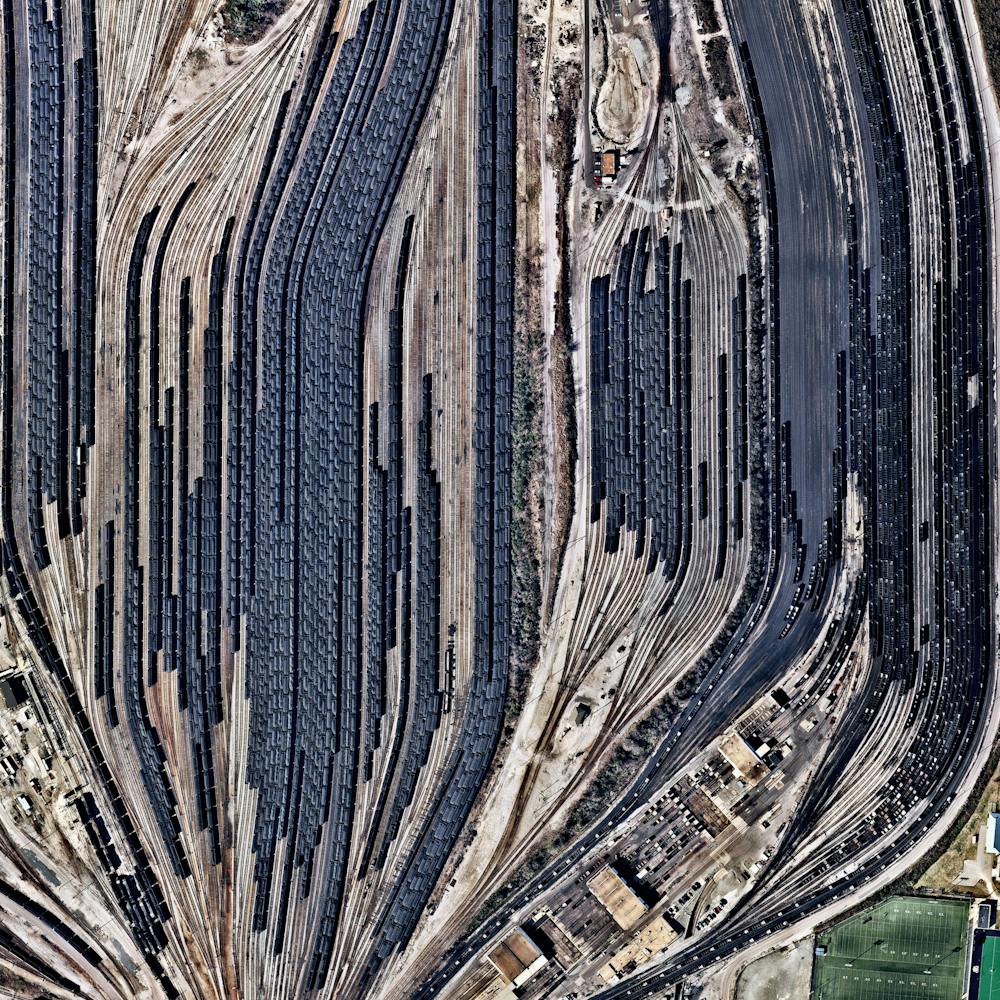

Lamberts Point Pier 6

36.875249°, -76.320260° - Norfolk, VirginiaTrain cars filled with coal are stationed in Norfolk, Virginia. Operated by the Norfolk Southern corporation, Lamberts Point Pier 6 is the largest coal-loading station in the Northern Hemisphere and serves at the temporary depot for the company’s fleet of 23,000 coal cars.

Nearmap

Lamberts Point Pier 6 Coal Railyard

36.875250°, -76.320250° - Norfolk, Virginia, USATrain cars filled with coal are stationed in Norfolk, Virginia. Operated by the Norfolk Southern corporation, Lamberts Point Pier 6 is the largest coal-loading station in the Northern Hemisphere and serves at the temporary depot for the company’s fleet of 23,000 coal cars.

Nearmap

Lop Nur Potash Evaporation Ponds

40.417972°, 90.795250° - Taklamakan Desert, ChinaThe Lop Nur Potash Ponds are located in the Taklamakan Desert of northern China. Potash, a form of potassium salt, is a major nutrient for plant growth and a key ingredient in fertilizers. The bright colors seen in this Overview occur because the water is dyed blue to absorb more sunlight and heat, thereby reducing the amount of time it takes for water to evaporate and the potash to crystallize.

Maxar Technologies

Michigan Tailings

46.408653°, -87.530031° - Negaunee, Michigan, United StatesTailings - the waste and byproducts from mining operations - are pumped into the Gribbens Basin next to the Empire and Tilden iron ore mines in Negaunee, Michigan, USA. Here, the materials are mixed with water to create a sloppy form of mud known as “slurry” that is pumped through magnetic separation chambers to increase the mine’s total output. For a sense of scale, this Overview shows approximately one square mile of the basin.

Maxar Technologies

Mir Mine

62.529461°, 113.993557° - Mirny, Eastern Siberia, RussiaThe Mir Mine is an inactive, open-pit diamond mine located in Mirny, Eastern Siberia, Russia. The mine is 1,722 feet (525 m) deep and has a diameter of 3,900 feet (1,200 m), making it one of the largest excavated holes in the world. Active for 44 years, the mine had an output of 10 million carats of diamond per year during peak production in the 1960s.

Maxar Technologies

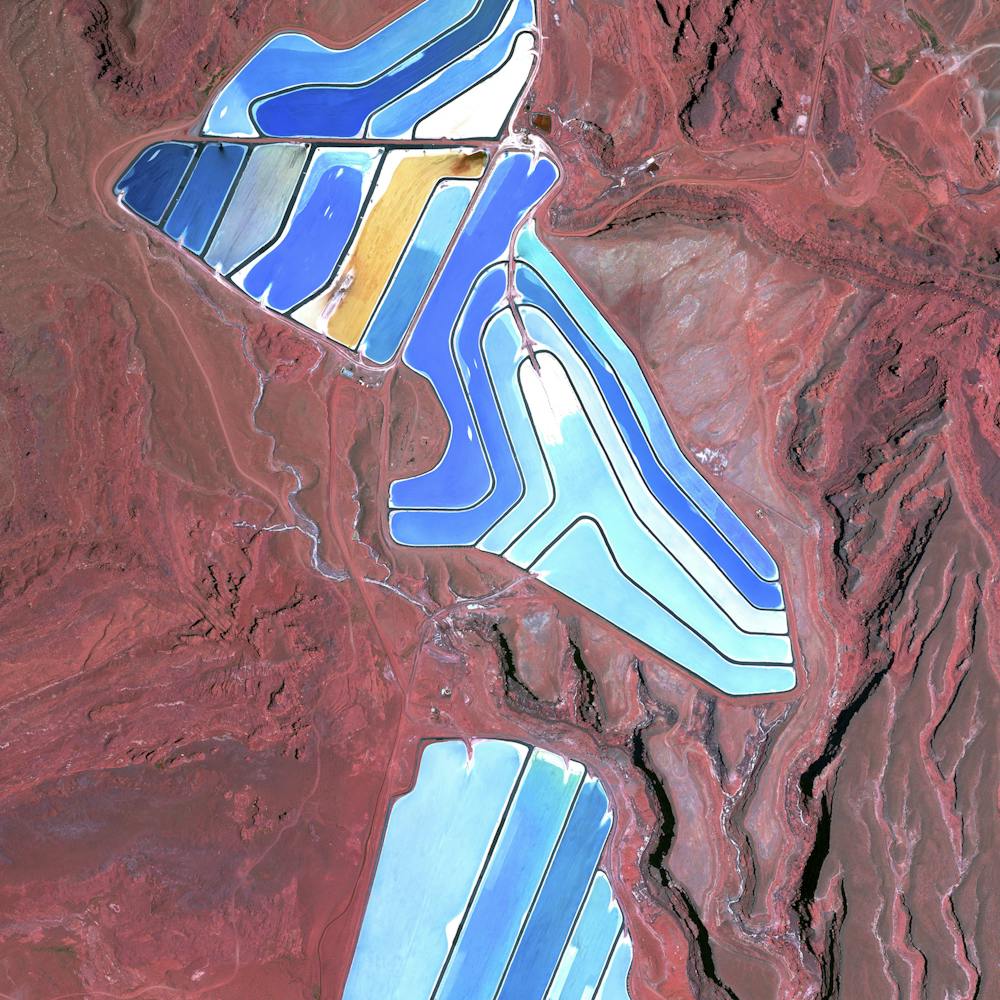

Moab Potash Evaportation Ponds

38.485583°, -109.684611° - Moab, Utah, USAEvaporation ponds are seen at the Intrepid Potash Mine in Moab, Utah, USA. The mine produces muriate of potash, a potassium-containing salt used widely by farmers in fertilizer. The salt is pumped to the surface from underground brines and dried in massive solar ponds that vibrantly extend across the landscape. As the water evaporates over the course of 300 days, the salts crystallize out. So why are you seeing such vibrant colors? The water is dyed with these vibrant colors to reduce the amount of time it takes for the potash to crystallize; darker water absorbs more sunlight so it gets hotter and the water evaporates quicker.

Maxar Technologies

Neves-Corvo Mine

37.573056°, -7.970833° - Castro Verde Municipality, PortugalWaste ponds are seen at the Neves-Corvo Mine in the Castro Verde Municipality in Portugal. Zinc and copper and the primary resources extracted from the mine and the byproducts of that extraction is sent to these basins three kilometers away. Typically, once waste materials are pumped into a tailings pond, they are mixed with water to create a sloppy form of mud known as slurry. The slurry is then pumped through magnetic separation chambers to extract usable ore and increase the mine’s total output.

Maxar Technologies

Oil Field Service Ships

5.263871°, 115.257724° - 5.263871°, 115.257724°Oil field service ships anchor offshore of Labuan, a territory of Malaysia that is located off the coast of Borneo. In addition to being an offshore financial center, Labuan is a support hub for deepwater oil and gas activities in the region. The economy of Labuan is heavily dependent on its fossil fuel resources, which account for 65% of its exports.

Maxar Technologies

Oil platform

46.166667°, 51.583333° - Kashagan Field, Caspian Sea, KazakhstanTwo boats pass through the sea walls surrounding an oil extraction platform in Kazakhstan’s zone of the Caspian Sea. This area is known as the Kashagan Field, an offshore oil field that is estimated to have a recoverable reserve around 13 billion barrels of crude oil. However, due to harsh conditions - specifically sea ice during the winter, yearly temperature variation from −35 to 40 °C (−31 to 104 °F), extremely shallow water, and high levels of hydrogen sulfide that eventually need to be removed from the extracted oil - many consider it to be one of the most challenging oil megaprojects in the world.

Maxar Technologies